Introduction

Smarture lab not only focuses on improving the existing manufacturing capabilities through establishing new theoretical frameworks but also aims to create new manufacturing capabilities that did not exist before. Our research is focused on the interplay of smart, sustainable, and advanced manufacturing, addresses the different levels of product, process, and system, and spans over many topics including robotics, additive manufacturing, future electronics, cyber-physical systems, product design, and healthcare. A few of our research directions are highlighted below:

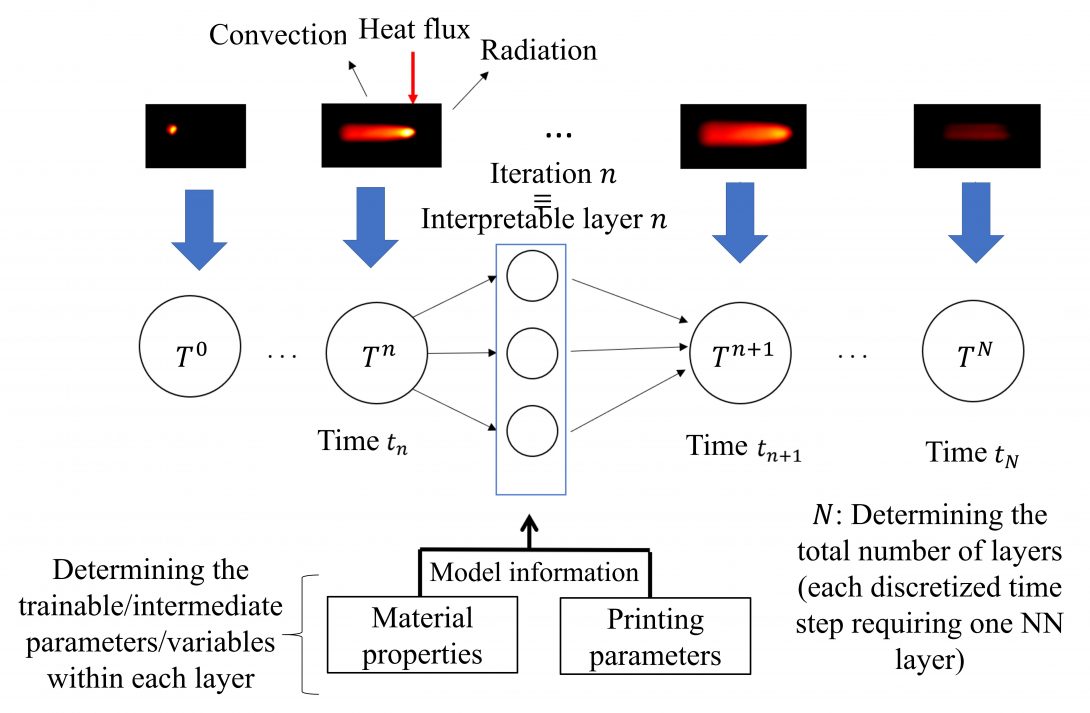

Physics-Informed Learning and Inference for Smart Additive Manufacturing

Additive manufacturing (AM) is a powerful emerging technology for the manufacturing of products with complex geometries using a variety of materials. However, despite the promising potential, due to the complex process fluctuations and material variability, process control towards ensuring product quality remains a huge challenge. Artificial intelligence (AI) has provided enormous prospects in additive manufacturing toward smarter design, process control, and quality assurance. We work on new frontiers and applications of AI and advanced data analytics in AM, especially physics-informed AI to enhance model interpretability, scalability, generalizability, and performance.

Next-Generation Printed Electronics for Enhanced Performance and Durability

The Aerosol Jet printing process is a micro/nano-scale additive manufacturing method that introduces unique advantages over conventional electronics manufacturing techniques, including higher resolution and conformal printing. We explore novel scientific machine-learning approaches including the recent advances in physics-informed machine learning for high-fidelity computational modeling of the complicated process-structure-property relationship to enhance electrical behavior and durability in extreme environments.

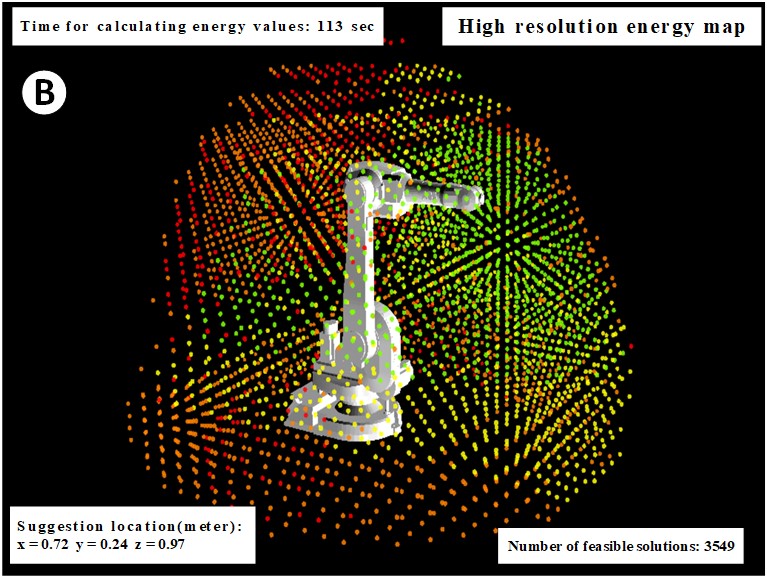

Multi-Robotic Manufacturing and Collaborative Robots

Industrial robots are important components of today’s manufacturing systems and are adopted in a wide variety of applications including manufacturing, inspection, assembly, recycling, and material handling. Next-generation manufacturing consists of smart collaborative robots that can safely and efficiently work together with each other as well as with human operators towards a specific goal. We work on creating novel smart quality-aware collaborative robotic platforms for faster, safer, and more efficient manufacturing.